News

Circular economy and sustainability with Italfimet's recovery plants

Circular economy and process sustainability are top priorities today for companies in the jewelry, costume jewelry and high fashion sectors. Recover, refine and reuse are three key words to inspire closed-loop productions oriented to maximize the value of each raw material and decrease waste, pursuing significant savings and generating further value. Italfimet has always paid special attention to the design and realization of plants for the recovery of gold, silver, platinum, palladium, copper or rhodium from the different stages of galvanic treatment, with tailor-made solutions according to the characteristics of individual companies.

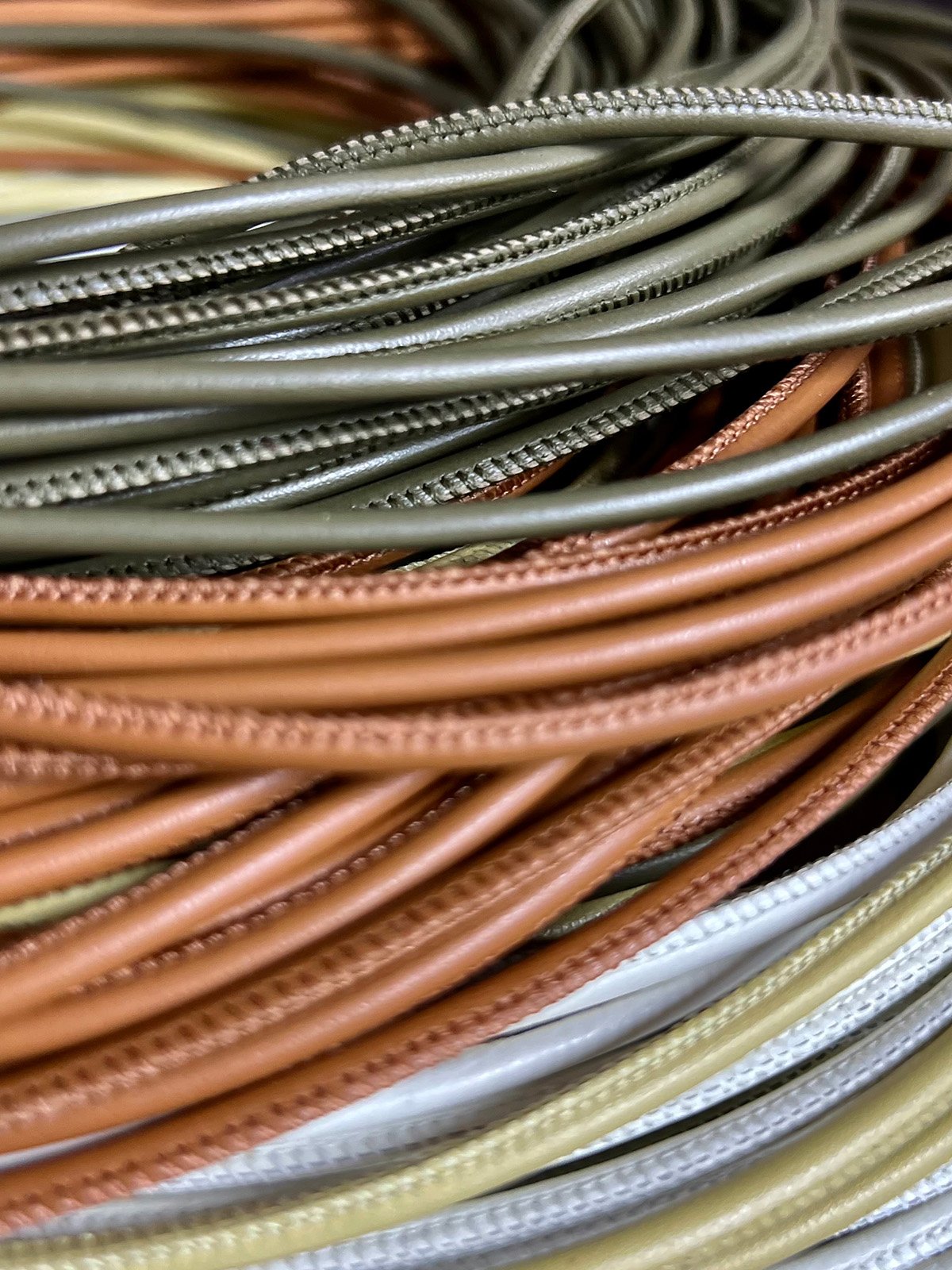

The correct and natural operation of the galvanic process involves the consumption of precious metals, with an inevitable dispersion of them in the passage between the different tanks for washing, degreasing or polishing. Precious metals are also present in the processing waste and are deposited on the frames and binding wires during the electroforming process. The real challenge, then, is in recovering and reusing them. Italfimet's catalog presents solutions for the various stages of treatment with plants for complete recovery of the precious metal that, combined with systems for refining and creating new galvanic salts, allow for reintroduction into the operating and working cycle, thus going on to realize a true circular economy model.

An additional technology patented by Italfimet to pursue waste and cost reduction is the RAEP® Anti-Pointing Effect Rectifier, which reduces precious metal waste in the production cycle and defects in the final product due to areas of high and low current density within galvanic frames. This innovative system cuts and redistributes the current evenly in the different internal and external areas of the frame, achieving greater homogeneity in metal accumulation, less dispersion, and higher final quality of the individual accessories. "Process sustainability," explains Diego Liberatori, foreign sales manager, " is pursued with plants that are custom-designed according to the productivity and needs of different companies. Italfimet is a unique and reliable partner capable of directly supplying the chemical, plant engineering and electronic equipment for galvanic treatment, with turnkey solutions for the entire supply chain or with the supply of individual technologies at the service of the production process, among which are also those oriented to the recovery and re-introduction of precious metals in the perspective of circular economy."