Evolution Tech Srl

EVOtech 3200 mm, the new soft embossing system for enhanced defect coverage

ABOUT

Created from the union of several partners who have worked in the field of tannery machinery for several years, the Evolution Tech company specialises in the construction of continuous presses for the tanning sector, with solutions that stand out on the market for their high technological content, repair assistance, and supply of components. In addition to the production of rotary presses and maintenance, the company also produces components for tannery machinery such as electrical panels, machine management software, raw and finished cylinders, and automation systems. The company’s flagships are maximum reliability, product quality and client focus.

FOCUS

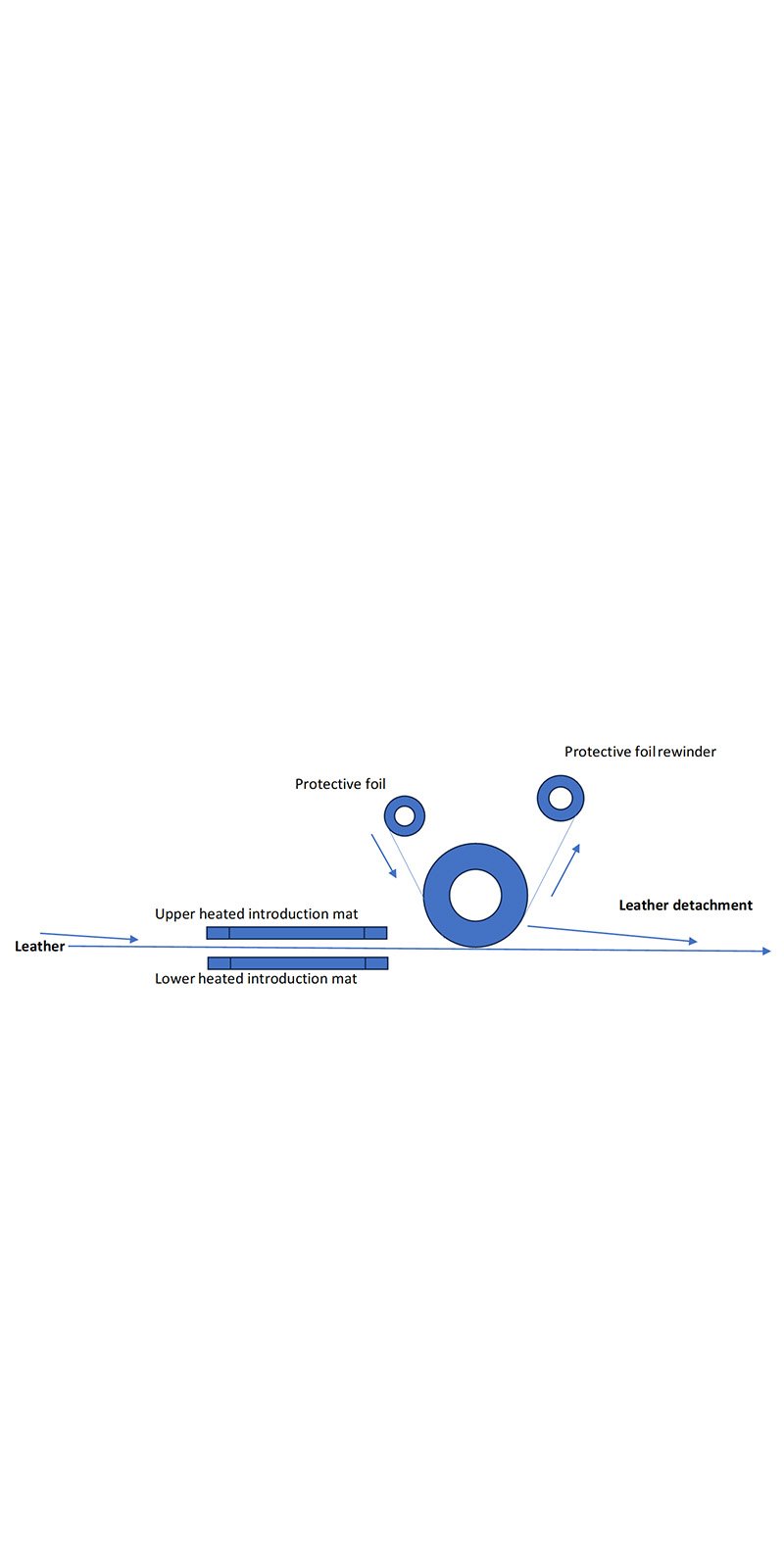

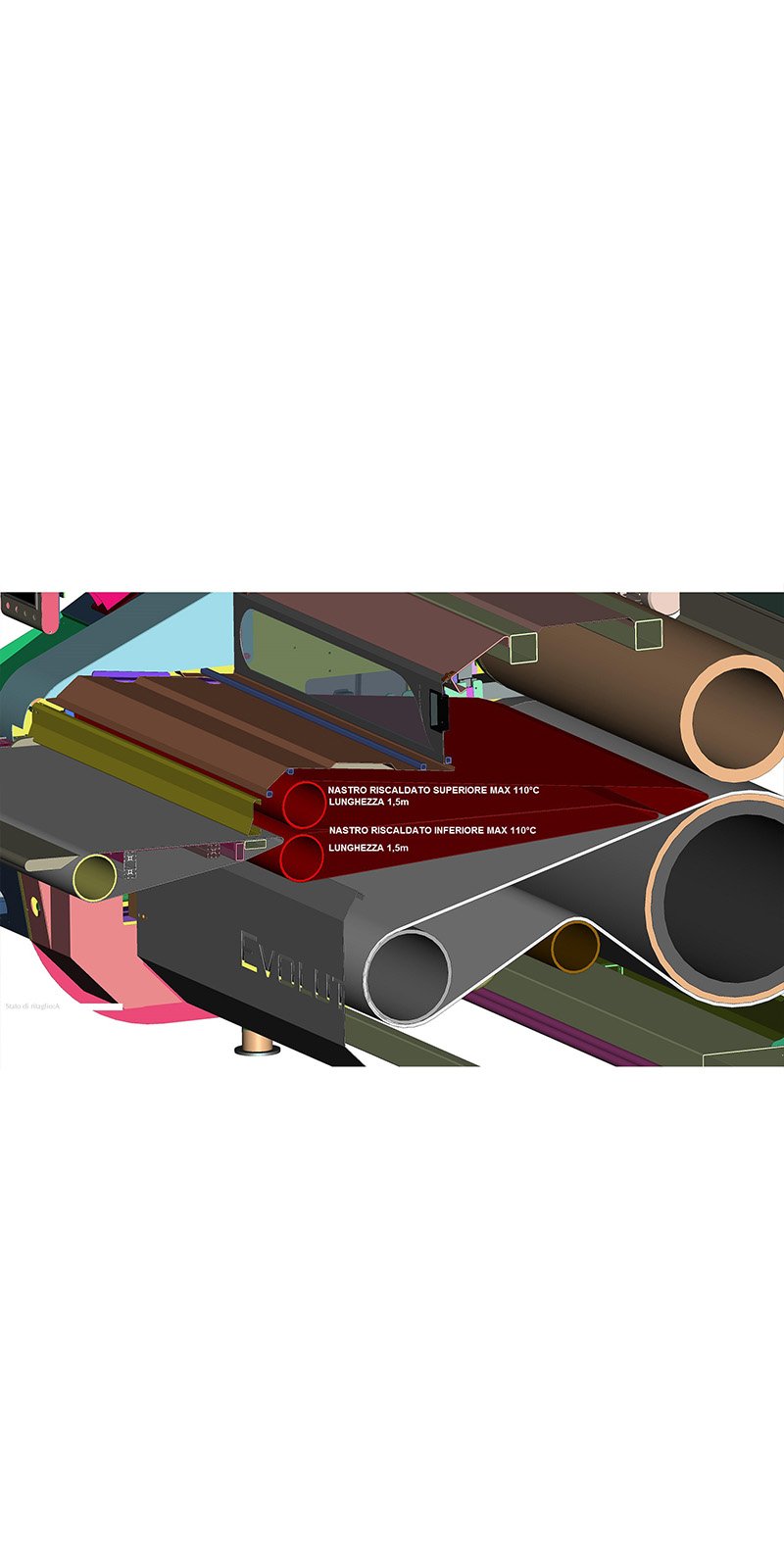

EVOtech 3200 mm is the new system by the Evolution Tech company for embossing and covering defects by means of engraved or smooth cylinder and protective film. The innovation of this moulding system stems from the combination of chemistry and mechanics with the aim of shaping the finish rather than pressing it. To do this, the company has worked in collaboration with an established partner in the field of leather chemistry. In fact, the process starts with thermoplastic products specially designed for leather finishing that mould themselves at low temperatures, ensuring an even distribution. A spray or roller machine is required to apply the special finishing mixture to the leather; once dried and suitably insulated, the leather enters the EVOtech process which, with its “patented” heated belt introducer, brings the resin to a temperature of 85° C until it is soft, while the smooth or engraved cylinder, finding this heated resin, is able to mould it, shaping it uniformly. There are many advantages starting with the significant reduction of abrasions, scars and defects of various kinds, as well as the possibility of obtaining a very smooth and soft skin with a deep design because it is obtained by a low-pressure fusion.