David Leather Expressions

Special processes for the Luxury sector: new combinations of techniques and out-of-the-ordinary effects

How do you translate a mood into a fashion object?

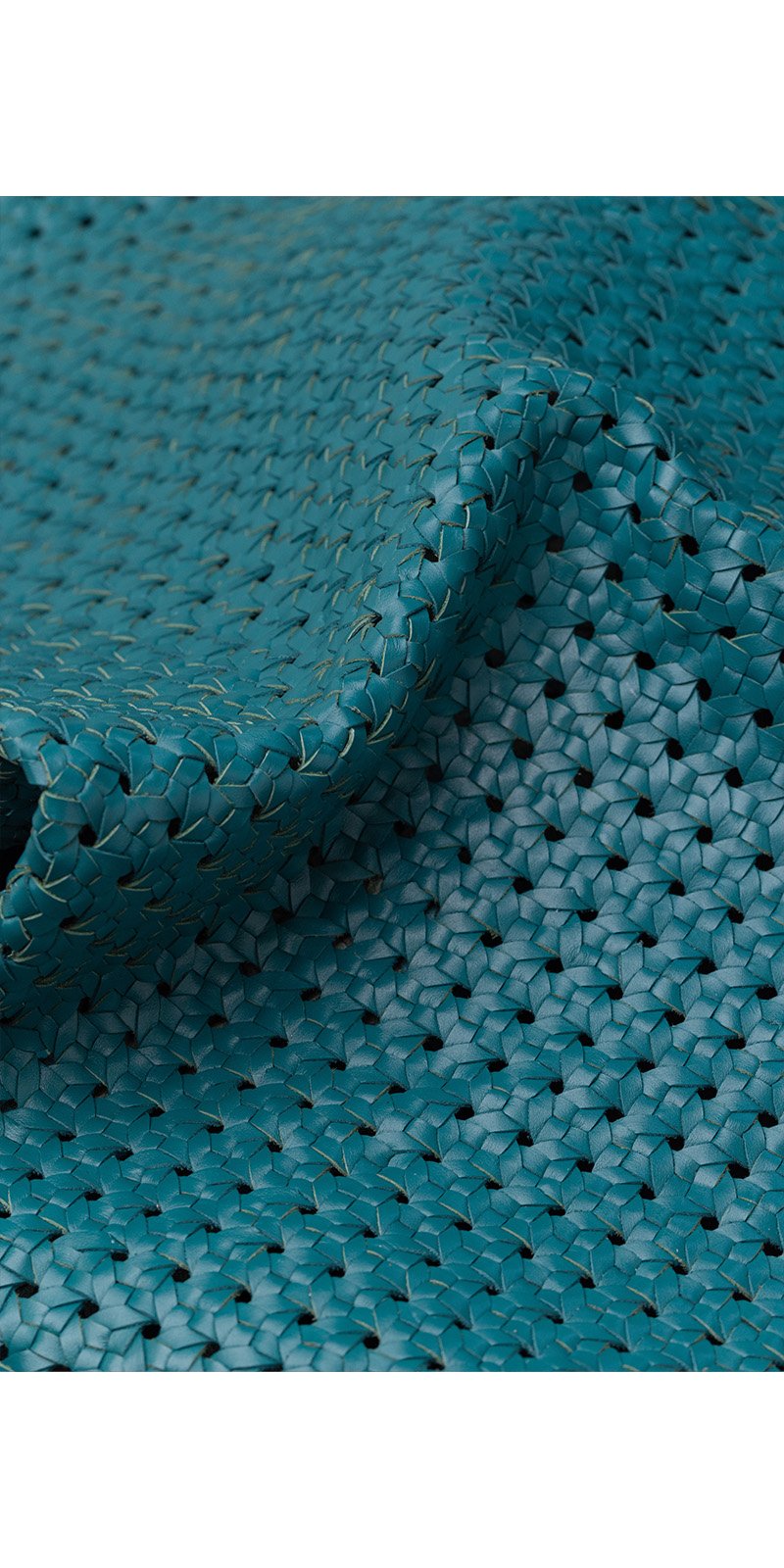

We spoke about this with Paolo Quirici, owner of David Leather Expression, a company that offers a quality, tailor-made services for the development of exclusive leathers ranging from weaves to macramé, from embroidery and handmade items to 3D relief prints.

What are brands looking for in terms of processing?

«Brands need continuous innovation; the most “basic” products can now be produced in-house. Brands are looking for veritable stylistic translators: once the storytelling of the collection has been launched, our task is to make proposals to translate the desired mood onto the material. Thanks to our mix of new technologies and expertise, we can provide a highly customised package of innovative solutions and endless combinations».

What is new in the field of R&D?

«We are using artificial intelligence to create 99% of the patterns and new designs. We are also focusing on making products that are increasingly technical: we have selected special fabrics to pair with leathers to create a high-performance combination suitable for leather goods. As far as woven fabrics are concerned, we are going stronger in our sartorial development, creating not only the “base” but also finished products such as bags, woven shoe uppers, and semi-finished products with avant-garde shapes and designs. We produce more elegant and extra-luxury items not only for fashion, but also for the automotive, nautical, interior design, hotel, and private jet sectors».

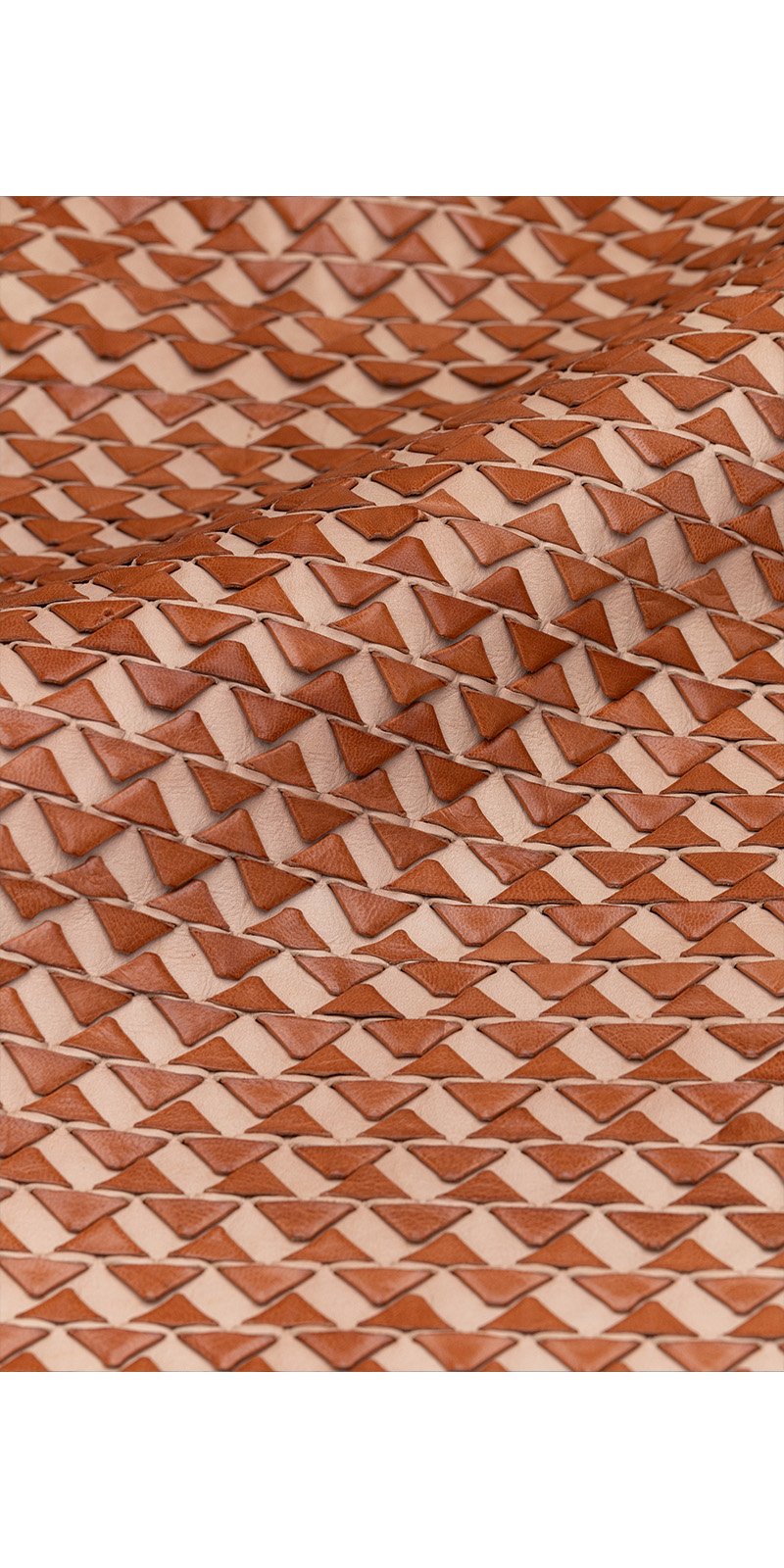

Let’s talk about Reliefin, what are the features and advantages compared to other embossing techniques?

«The system we have patented has the advantage of enhancing the three-dimensionality of the design without altering the natural characteristics of the leather and its softness, unlike heat embossing which gives a good, curved effect but creates hardening. It enables us to work on thicknesses from 0.7mm upwards without limits in thickness: we can even process whole hides, which is not possible with high-frequency embossing, which has measurement limits. It also does not require an implant and thus reduces costs and production time compared to traditional techniques».

Special and compound work is a favourite in the fashion world. Can you give us some examples of special projects you have worked on over the years?

«Over the years we have had the most diverse requests; to name but a few, we have created a stretch pony skin with two-colour patterns, carvings with denim fabric on a fluorescent base, and animal prints that recreate the real effect of fur. We have also created a 1 mm round leather yarn which, when treated with special industrial wool processing machinery, gives life to leather ribbed sweaters. These are just some of the projects conceived by our creative workshop, which is able to give concrete form to any of our clients’ ideas».

Finally, let's talk about the light effects on leather

«Thanks to digital instruments, we have created a 3D print that produces an innovative reflective game of four-colour reflections: if we take an inscription, for example, on each of the four sides we can use a different colour; the result is a very bright effect. We created a leather with an ultra-soft metallic and iridescent varnish; as for weaves, we inserted a metal foil that recreates a striking mirror effect».