News

Marcom Import Export: "Sustainability does not exist without product traceability"

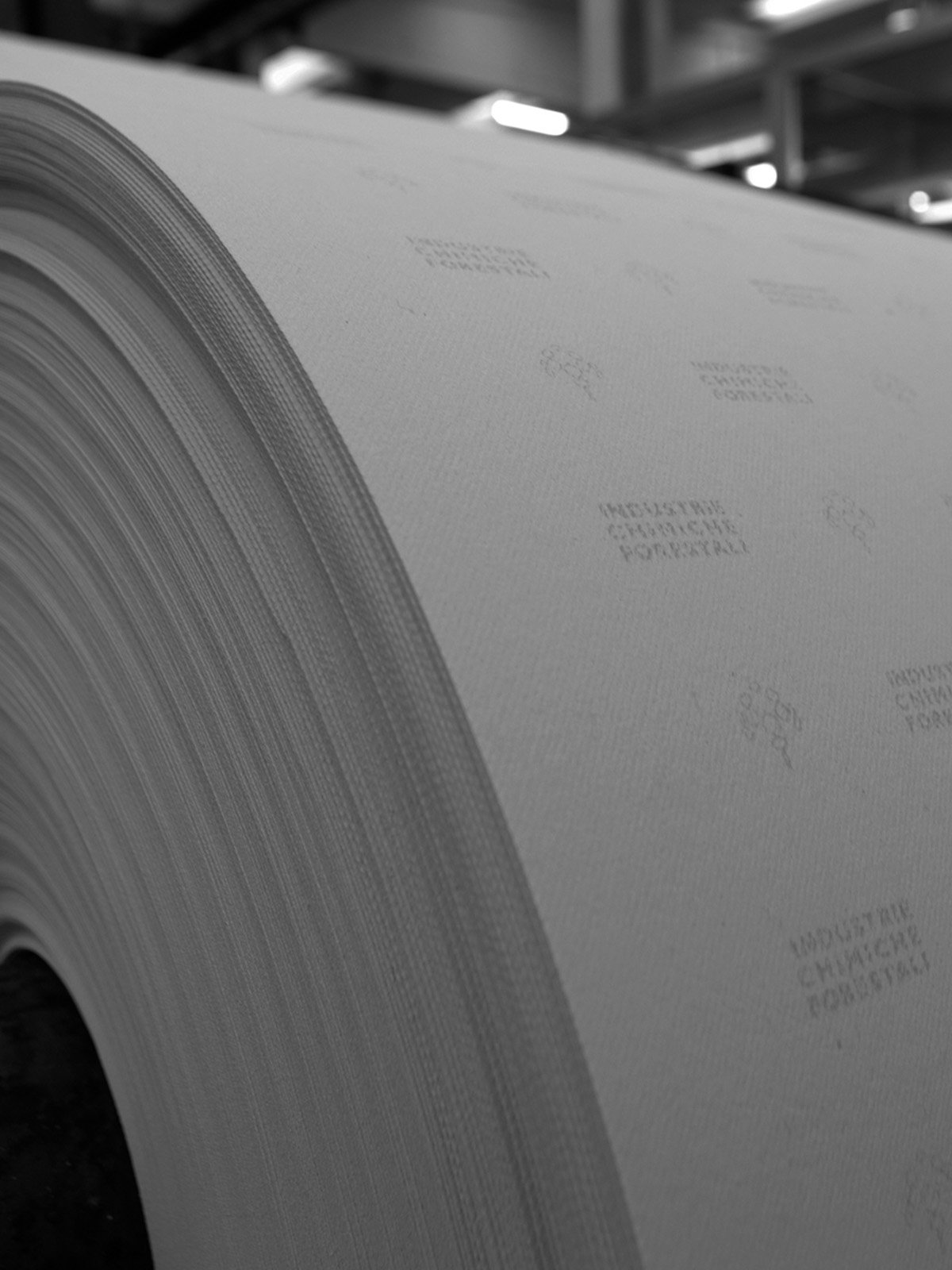

"Beyond directives, companies will have to address product traceability, if only to shelter themselves from problems. But mostly because without it, sustainability does not exist." While waiting for the European Parliament to give the green light to regulations on the subject, MARCOM IMPORT EXPORT, which has been custom manufacturing steel foils for the footwear industry since 1997, has stepped forward, aware that beyond the regulations, it is the market that is moving in that direction.

"We offer traceability systems in both analog and digital modes," explains Marco Marucci, owner of the company. "On the one hand, we have a physical label that shows the product description, batch and quantities. On the other, a digital production code, readable through QR code, which allows us to trace its history from birth to delivery. The goal is to identify the origin of a problem but also to ensure adherence to sustainable processing principles."

Making data available for each batch, however, is not enough: for traceability to be functional, it must have a physical match. "Our company keeps a sample of each product in its warehouses for three years," Marucci clarifies. "The batches are available to customers, who can check both their quality and the various aspects related to sustainability. A need that also arose for the purposes of the Chinese GB/T 28011-2021 regulations regarding the technical data of footwear foils."

Today, thanks to the Smart Shank system, MARCOM IMPORT EXPORT is able to equip each foil produced with an RFID and NFC technology chip with two memories: one immutable that represents the product's identity card, useful in the B2B segment; the other one registerable with a code chosen by the producer that allows the footwear to be identified within the entire supply chain up to the store, expendable also on the B2C front to "talk" to the end consumer. A useful system also in the area of anti-counterfeiting.

"If a brand receives a complaint, it will trigger an investigation. But if there are no traceability systems along the supply chain, how to figure out where the problem originated? The direction is toward establishing due diligence where the prime contractor will have to act on the various sub-suppliers: companies need to start preparing. We are already ready and have structured ourselves to be able to identify our products both on paper and physically, even after time has passed."