News

Where does the sustainability of the Italian metal fashion accessory supply chain stand?

This question was tried to be answered by the Physis Consortium on April 11th in Florence during a meeting that called on members, industry insiders and institutions. The 30 or so players in the metal fashion accessory supply chain who have already joined the Physis Consortium operate in manufacturing, galvanic treatments, plant design and production, raw materials and chemicals. During the event, the Consortium presented its initiatives on sustainability of the supply chain. "Since the consortium was born," emphasized Physis Consortium technical director Ester Falletta, "we have already collected the concrete instances of the various faces of the supply chain, making ourselves promoters of evolving needs. Among the first works in progress is an international study on standards for the responsible sourcing of precious metals and the definition of 'recycled.'" Indeed, it is becoming increasingly common for accessory companies to practice the use of recycled metals to lessen the environmental impact of their processing.

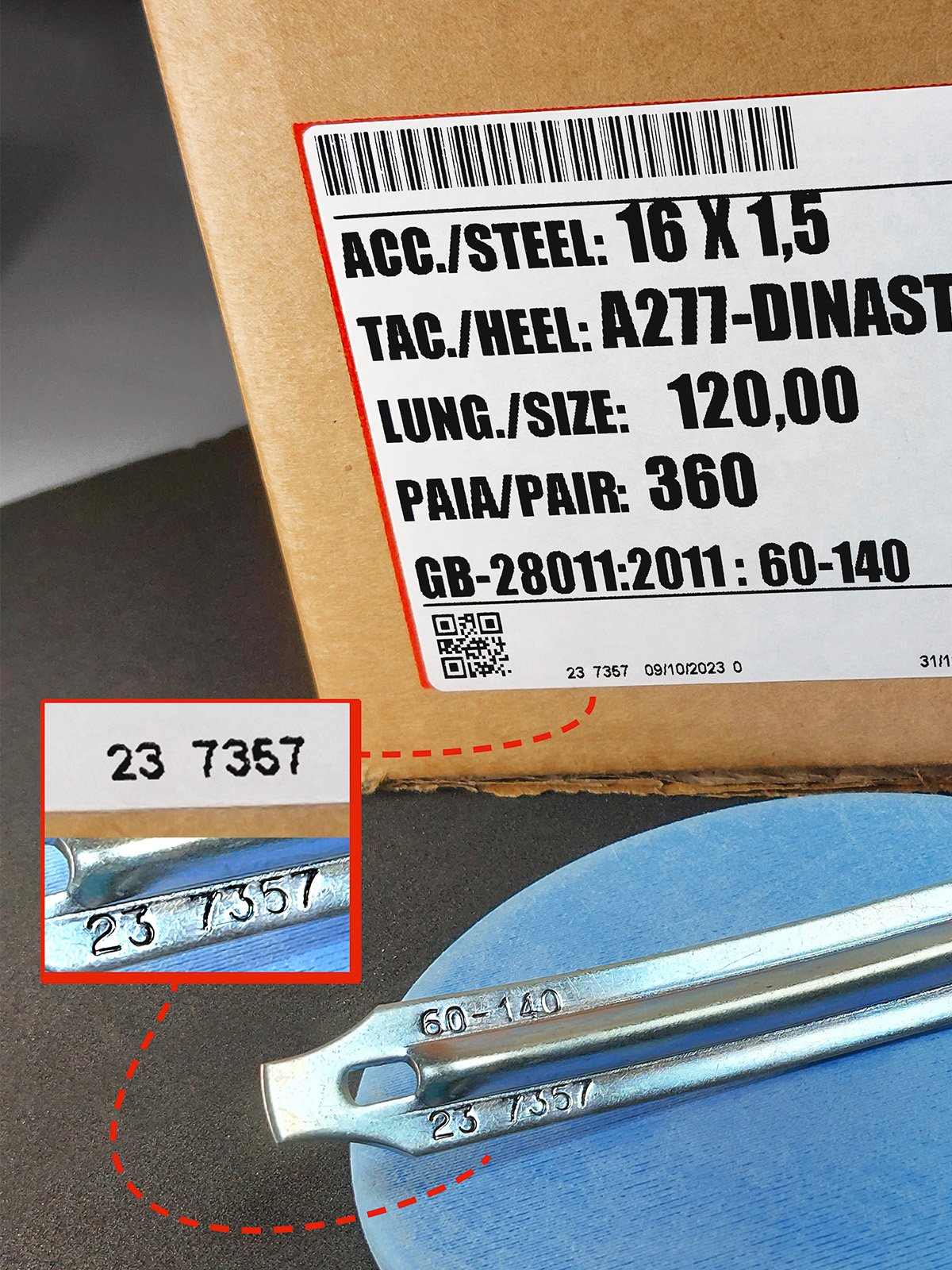

When this choice is not possible, the compass is an ethical one: metals must come from sites (mines) where workers' rights are respected as well as from geographic areas that are not subject to deforestation. This sustainable approach introduces an additional tool, the promotion of which is another key part of Physis' mission: the digital passport of the metal accessory viewable via QR Code. Specifically, the Digital Product Passport (DDP) is a device devised by the EU to make both end consumers and control bodies aware and informed about the products being purchased and all its components. The Digital Passport provides the "liquid" identity, in this case of the metal accessory, with details on its ecological footprint, physical and chemical properties, recycling possibilities, and so on. This is a mandatory step that companies must adapt to very soon, as DDP adoption is expected by 2027 at the latest. It is understood that the fashion supply chain is expected to do an immense amount of data collection work, and the challenge of entities such as the Physis Consortium is to help the industry evolve in a homogeneous way so that all its components remain competitive in the market. With this in mind, it will also be very interesting to see the developments of the synergy between Physis and the international ZDHC (Zero Discharge of Hazardous Chemicals) program represented at the Florence meeting by Elisa Gavazza, who illustrated the ZDHC" Roadmap to Zero program of ZDHC" and the MRSL project specific to the metal accessory. ZDHC was created at the behest primarily of luxury brands to steer fashion manufacturing value chains toward the use of safer chemistry. Its main goals are to replace and/or eliminate where possible hazardous chemicals from the entire production chain; promote safer chemistry; and focus on training and a culture of best practices to improve chemical management at the production level. ZDHC's main tool is the MSRL (Manufacturing Restricted Substances List), a list of chemicals that are banned or can be used within very narrow limits internationally. Physis' collaboration with ZDHC aims to draft an ad hoc MRSL for the metal accessory value chain, a tool that would fill a strategic manufacturing gap. So far, in fact, the supply chain has been oriented with a more generic MSRL that does not cover all the environmental sustainability needs of the sector.