News

Italsform's 40 years: from beginnings to soles for luxury brands

“With tenacity and perhaps also with a bit of recklessness, we began to make ourselves known and from there the contact with the first luxury brand was sparked: working with high-level clients helps to make you better, and our continuous research and evolution has allowed us to establish ourselves in the sector.” Recounting the beginnings of Italsform is Viviana Pirini, administrator of the San Mauro Pascoli (FC)-based company, a reference point for the production of semi-finished products, soles, leather and rubber monoblocks for the luxury world.

He does so as the company approaches its 40th anniversary in August. “When Italsform was born, on the ashes of a previous sole mill,” he says, ”we were doing contract heel wrapping for shoe factories. Then we decided to take the plunge, buying the first machinery for making soles and moving to San Mauro. We received trust because we worked well, customer satisfaction has always come first for us. Despite the sacrifices we enjoyed creating what we are today. In the beginning no one expected anything from us, because we were new: today, as we turn 40, we are a reference point for many.”

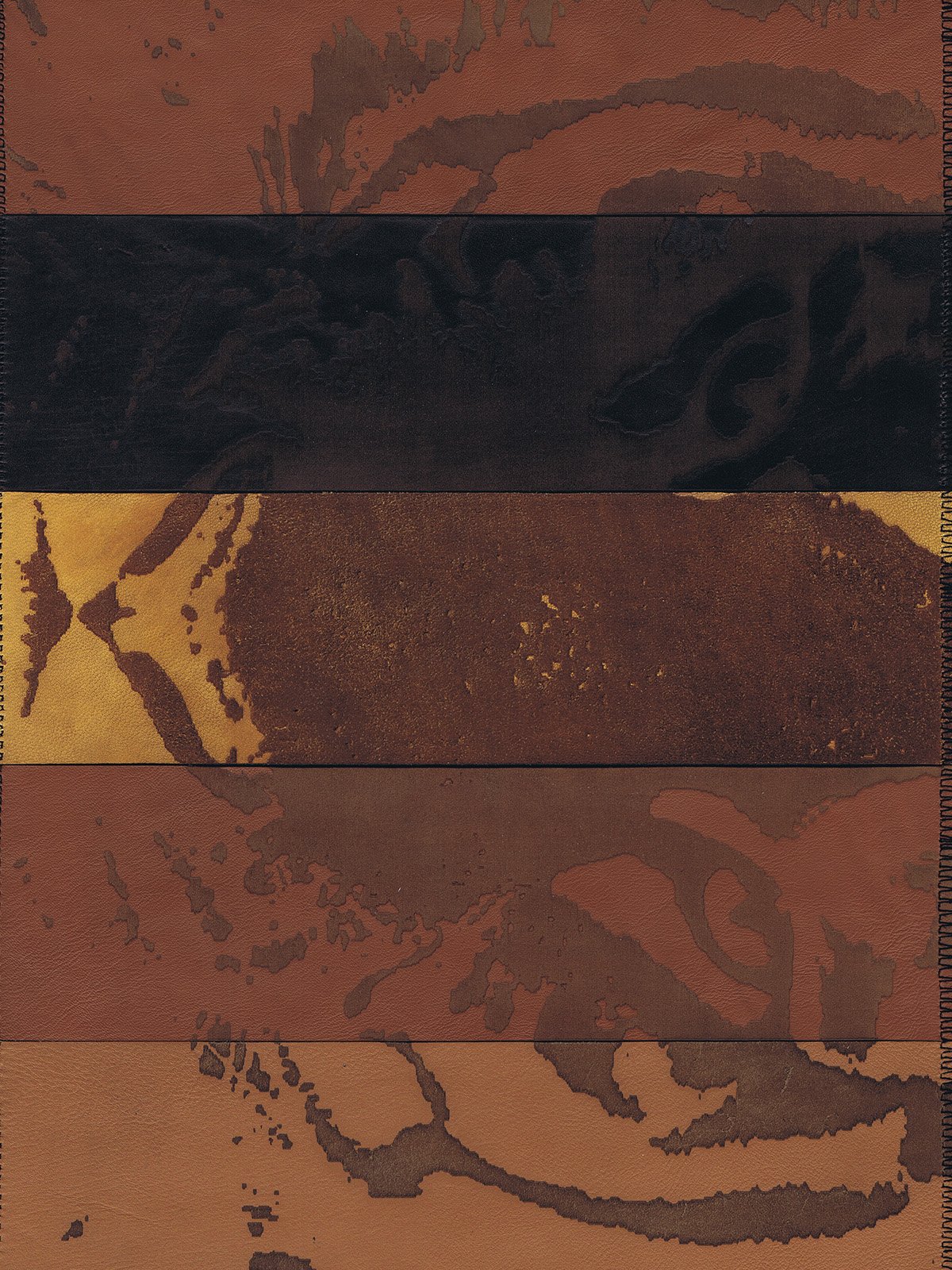

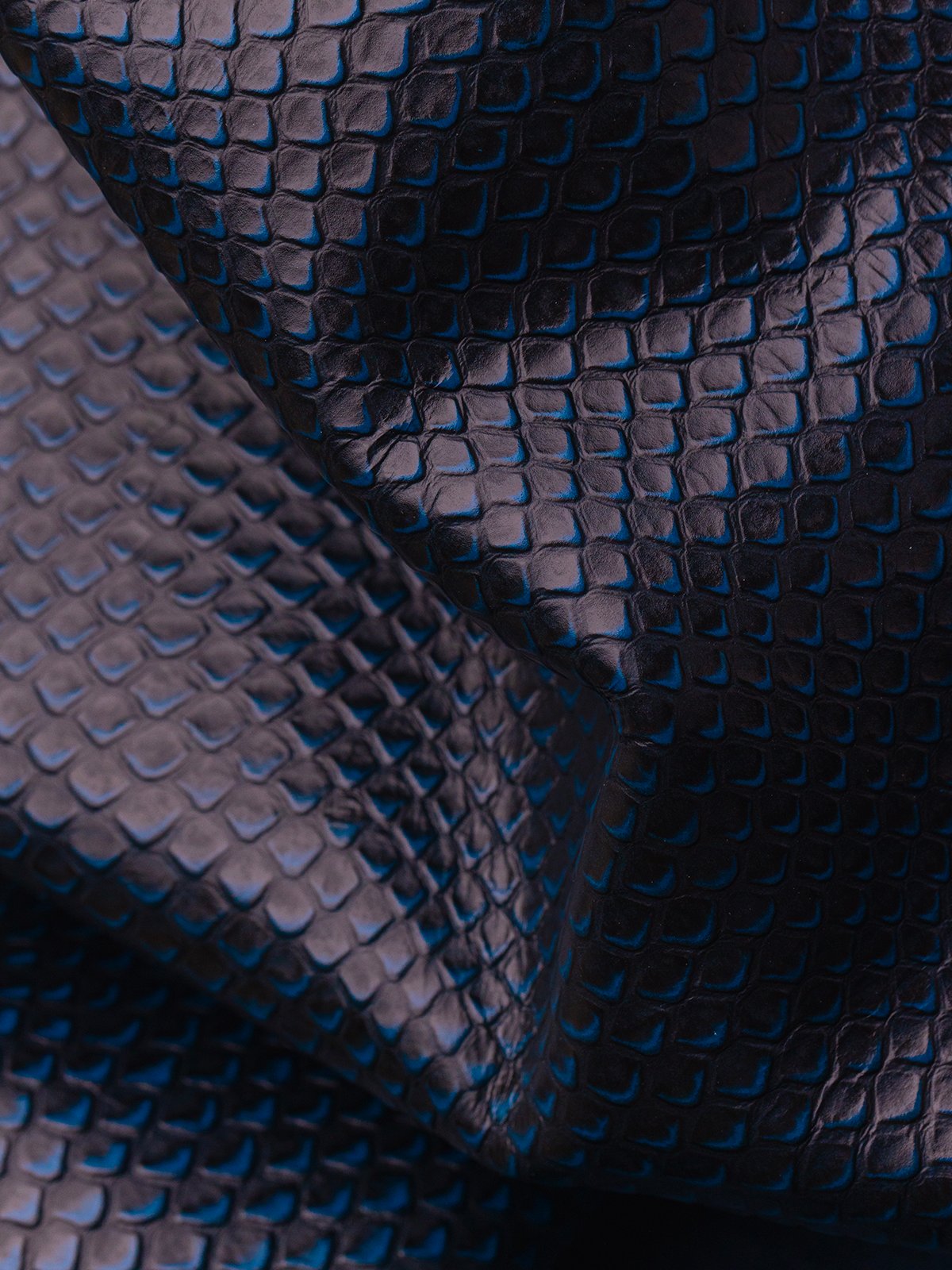

A partner of excellence for luxury brands, Italsform has always focused heavily on research and innovation, thanks in part to the creative mind of Davide Sarpieri, co-administrator and modeling manager. “We always bring new products to the fair, we are among the few who are constantly trying to come up with something different,” Pirini explains. ”We love to experiment, a feature much appreciated by the style offices. Among sculptural creations, carvings and special colorings, the sole made of wood logs and the sole made of coconut fiber stood out.

“Our main material, however, remains leather on which we do a great deal of research, using only that of certified tanneries, treated with natural tannins,” he adds. ”Today we are asked to act in the least polluting way possible and, also for this reason, we are working on achieving environmental certification. Attention to environmental issues is also found in the decision to have installed a photovoltaic system that covers more than 50 percent of the company's electricity needs, as well as in the use of recycled packaging, including adhesive tape.