News

Squaring: how to test a quality electroplating coating

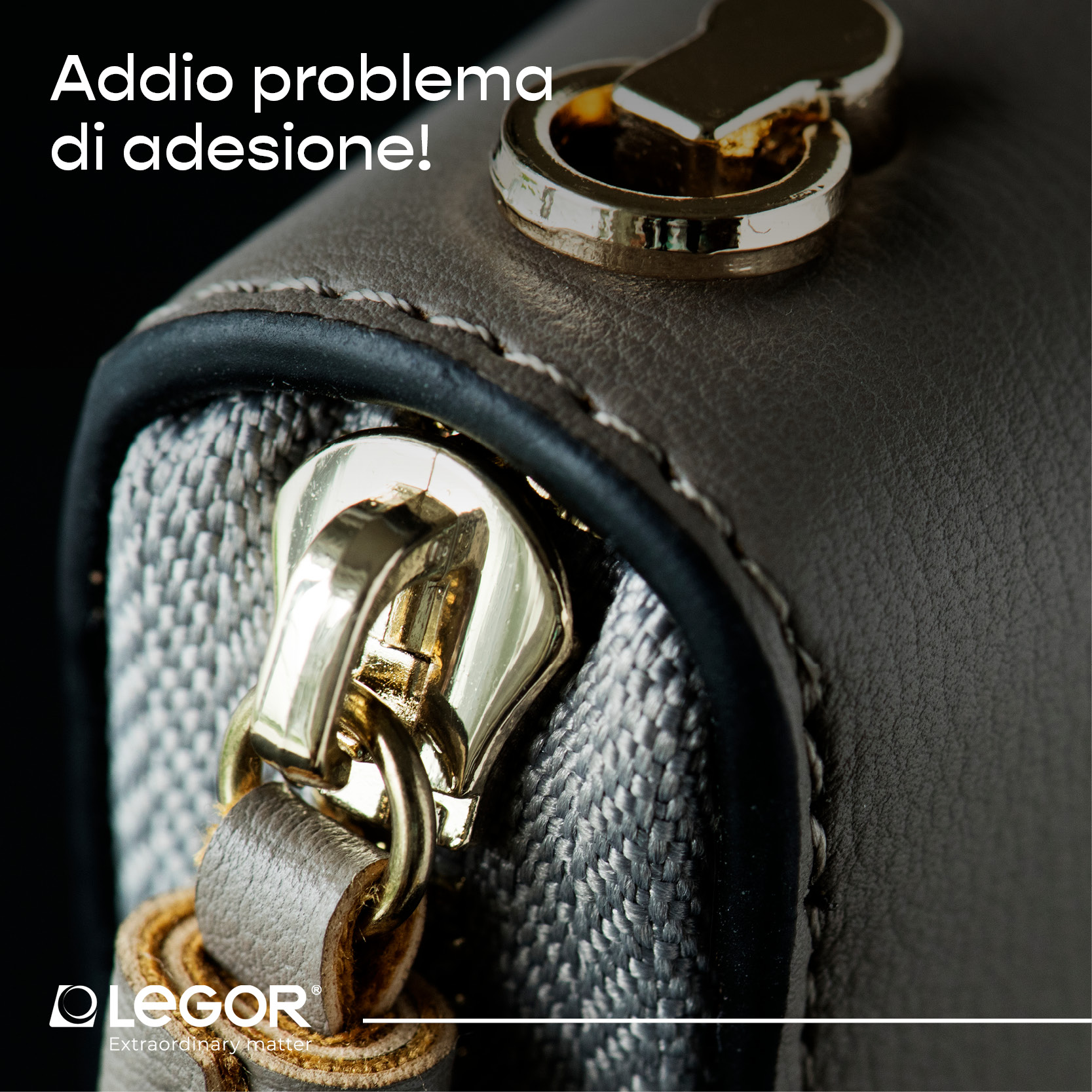

A quality galvanic treatment represents an indispensable step for the luxury industry. In fact, galvanic coating not only beautifies a fashion accessory, usually made of brass or zamak, metals that are not noble and have poor aesthetic qualities, but also has a crucial function: to improve its durability and resistance to corrosion. It therefore gives accessories (chains, buckles, studs and other types of metal hardware) performance in line with that of a product intended to last.

What helps maintain these expectations is the proper adhesion of the metal coating to the object itself. This is an aspect in which Legor, an international benchmark for precious metal science serving the gold-silver, fashion and electroplating-industrial sectors, invests heavily. Legor's R&D team is able to provide timely analysis and, as a result, customized galvanic cycles that ensure maximum adhesion and color durability.

Verification of proper coating adhesion is provided by the squareness test, regulated by UNI EN ISO 2409:2020, which provides a method for evaluating the resistance of galvanic deposits to detachment. The procedure, specifically, involves making a grid incision on the film with a cutter or appropriate metal blade, reaching down to the substrate. Next, equidistant horizontal and vertical incisions are made until the lattice is created on the test surface.

Finally, an adhesive tape is applied to cover the etching area, which is then vigorously removed. The last step is to visually observe the lattice area to determine the result: if at the time of tearing with adhesive tape the coloration or deposit comes off the object, it means that the test has failed and the poor adhesion of the coating may be attributable to several factors within the electroplating cycle used.