News

Soul, here is the futuristic soul of the lasering of the insoles

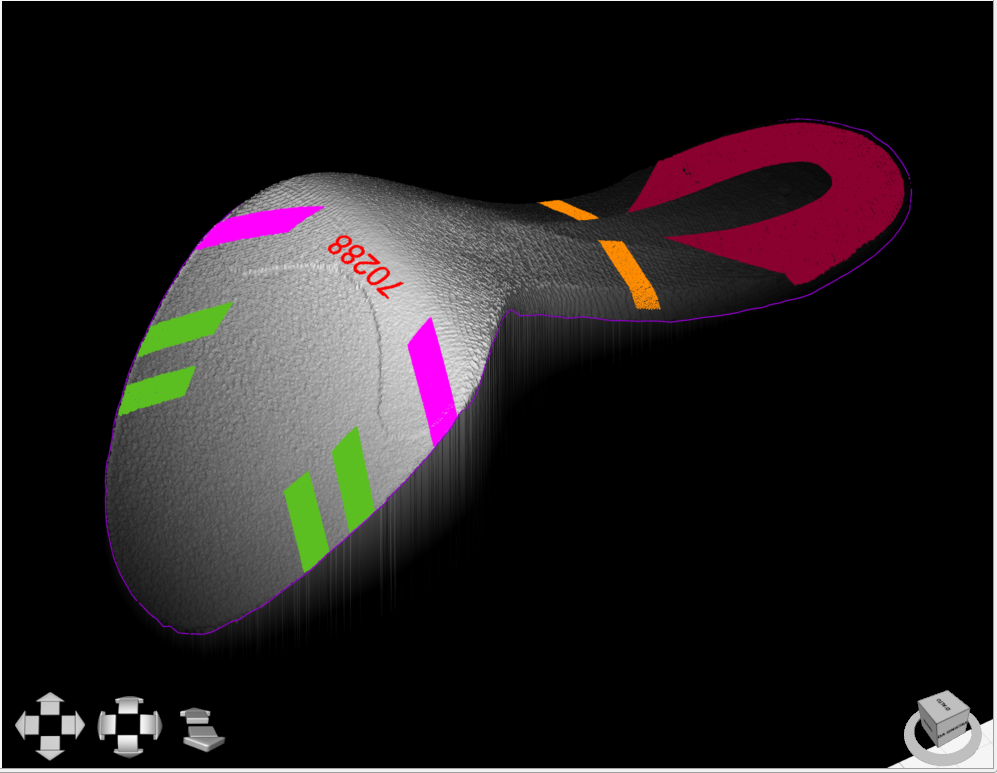

Three-dimensional scanners to bring the insole lasering system to a higher level, guaranteeing greater precision and a qualitatively impeccable final product, through a totally automated process. The new machinery is called Soul and is the latest frontier of Seit Elettronica, a Treviso-based company that creates technologically advanced systems for footwear. "Soul represents the first concrete application of a patent filed a few years ago - explains Edoardo Codello, sales director of Seit Elettronica. The novelty is represented by the integrated 3D scanners which allow you to recreate a digital version of each insole to be machined, thus eliminating the inaccuracies linked to mechanical processing."

"There are two advantages – explains Codello – namely absolute precision, which for footwear translates into increased comfort, quality and aesthetics, and the possibility of making the manufacturing process automatic, therefore not supervised by an operator». In fact, the machine works autonomously and is equipped with laser powers of up to 1kw, with an increase in power, therefore, compared to traditional products. This translates, where necessary, into greater productivity: an upgrade designed for companies that need to carry out production of a certain quantity and at speed. The size of the machinery also changes, becoming smaller, and there is automatic recognition of the material to be processed.

The system, already equipped with all the features of the previous models, including the motorized tilting system managed by software, represents the cornerstone on which subsequent innovations will be structured. "It is a platform on which we will base product development for the next 5 years – concludes Codello – with the possibility of adding further functions. The next step will be to equip Soul with software with a three-dimensional scanner that will allow automation of the drawing process that is impossible today. Advanced features that are very important for manufacturers."