News

The jewels of the future will be made of gold recovered from phones

Credit: Prada

Credit: Prada

The jewels of the future could have an increasingly high component of precious metals that come from a recovery process of electronic objects that we have at home. They are called RAEE (Waste from Electrical and Electronic Equipment) and are old cell phones, laptops and old-generation iPads that contain gold, copper, silver but also palladium and rhodium, which can be "extracted" from these devices to be transformed into coins, other components or even jewelry.

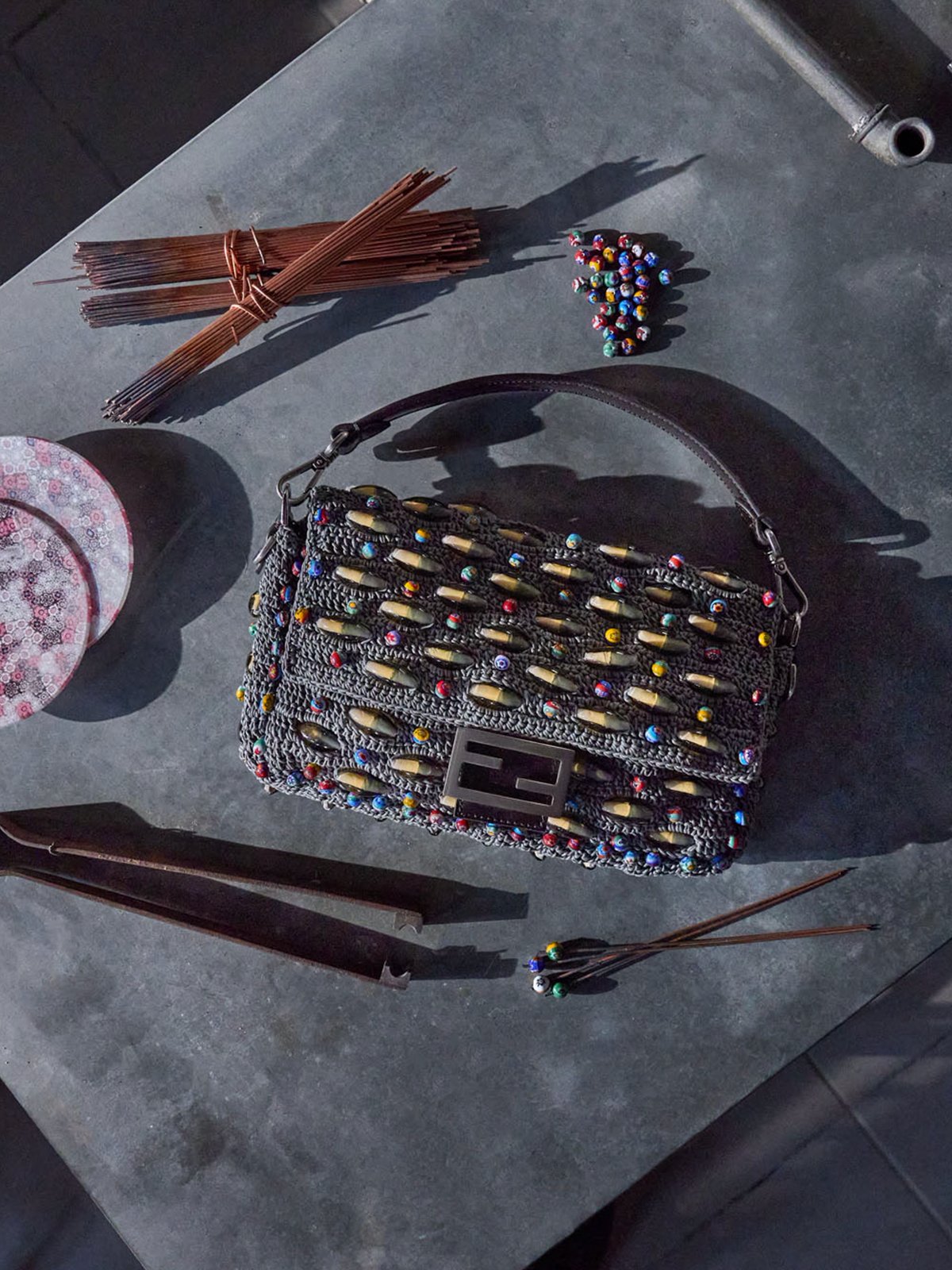

In fashion, there are already some companies that make open use of it: a few years ago Prada launched its Eternal Gold Fine Jewelry collection, made of 100% recycled gold, while Pandora recently announced that all its productions will be made entirely of recycled precious metals. Only a small part of these materials come from RAEE (the rest is instead a reprocessing of other jewelry or processing waste), but the hope is that in the future this figure will increase, so as to compensate for the ever-increasing demand for gold. The challenge is to encourage people to recycle and improve recovery processes to make them less impactful on an ecological and social level.

The answer lies in urban mining, as Omar Cescut of BTT Impianti, an Argentine company that deals with plants for the recovery and refining of precious metals, explains. “It is important to raise awareness among citizens, who in many cases do not want to go to the recycling center or are afraid of losing the data contained in their old devices, facilitating collection also through investments such as the installation of intelligent bins capable of destroying the data as soon as the devices are deposited. And then retain this waste in Italy, using new-generation plants that reduce the impact of the recovery process and improve its quality”.

In fact, the management of RAEE normally involves two possible paths: either the recovered devices are sent to countries where there are large furnaces, which melt the waste with a pyrometallurgical process to then recover the various precious metals, or they are sent to Africa where the metals, with a more dangerous and polluting process, are partially recovered due to the rudimentary technology used.

“Italy can manage its waste domestically - explains Cescut - thanks to smaller plants that avoid pyrometallurgy in favor of a hydrometallurgical process: the plant that we have just inaugurated uses a selective leaching process, which separates the various components using water, so as to perform a direct refining on the metals without any incineration with obvious environmental advantages. The ingots that are obtained are digitally certified, so as to guarantee a transparent supply chain for brands and end consumers”.