News

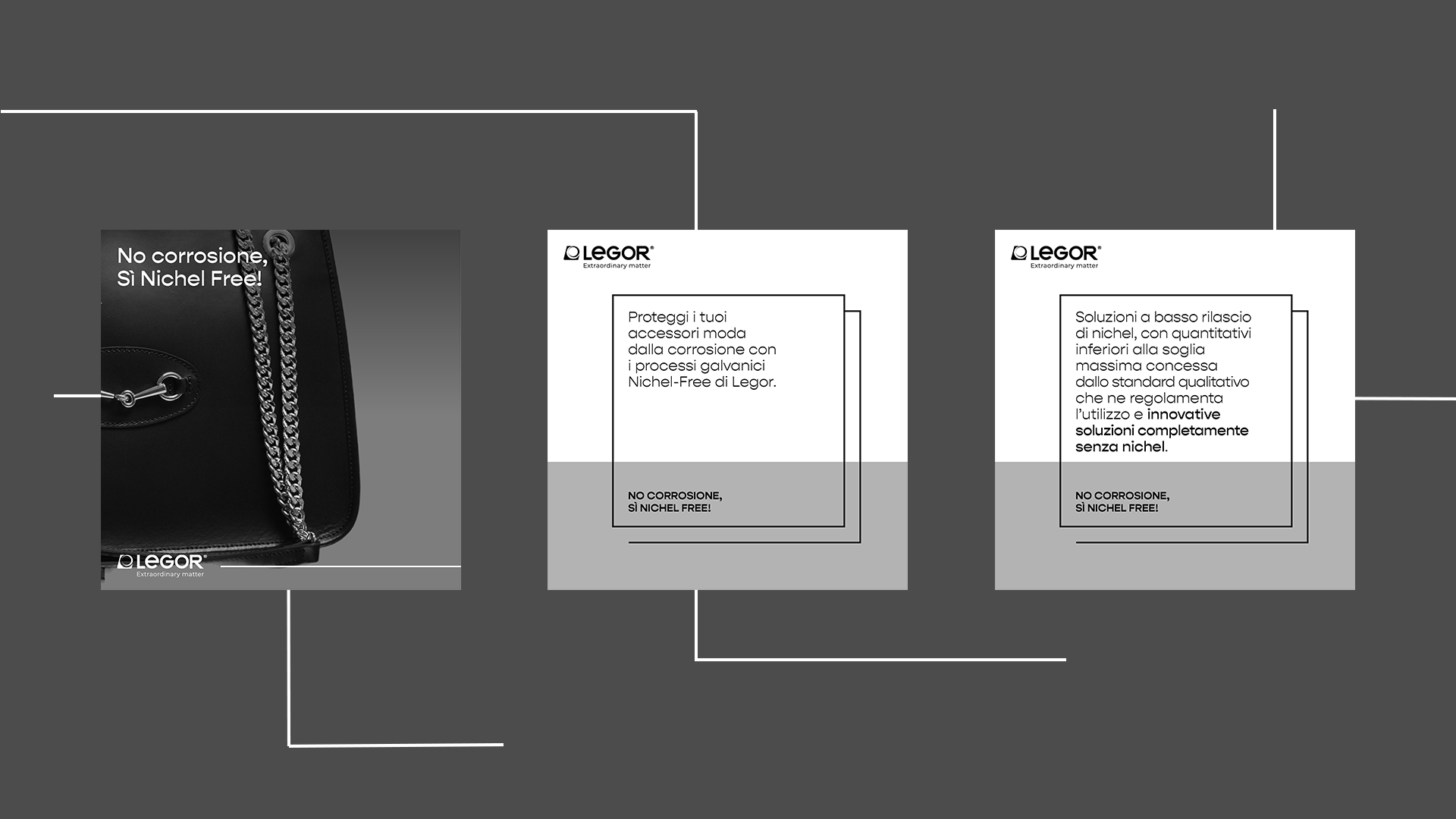

Nickel-free but corrosion-free accessories: solutions from Legor

Brass and zamak. These are the two materials commonly used to make fashion accessories. However, they are non-noble metals that, in addition to not having good aesthetic qualities, have low chemical inertness. A characteristic that leads them to develop corrosion phenomena very easily and often. Therefore, it becomes necessary to subject them to coating processes to meet market requirements, achieved through a series of galvanic deposits. Legor's research in the field has resulted in high-performance solutions that respect the environment and health.

In fact, coating processes are divided into two different types of processing: nickel-based and nickel-free. The latter are treatments that meet the most recent regulations, which severely limit the use of nickel, a material that creates allergies, not derived from the presence of nickel in the product, but from the release of nickel on the skin, which has led to its diminishing use in the accessory industry. Historically, there has been extensive use of nickel plating, which allows for shiny, bright, high-hardness, tarnish (oxidation) resistant deposits, making true barrier layers against inter-metallic diffusion.

So how to reconcile the performance of nickel with European regulations limiting the amount of nickel to be applied to articles? Depending on the requirements, Legor is able to provide two answers that guarantee the same performance and quality standards of brightness, hardness and resistance to oxidation. The former are Nickel Free galvanic solutions, therefore totally Nickel-free; the latter are Nickel Safe: a term coined by Legor to identify solutions with low nickel release, with quantities well below the maximum threshold allowed by the quality standards that regulate their use (such as the European standards UNI-EN 1811 or EN 16128).