News

HotMix, technology applied to chemistry for tannery

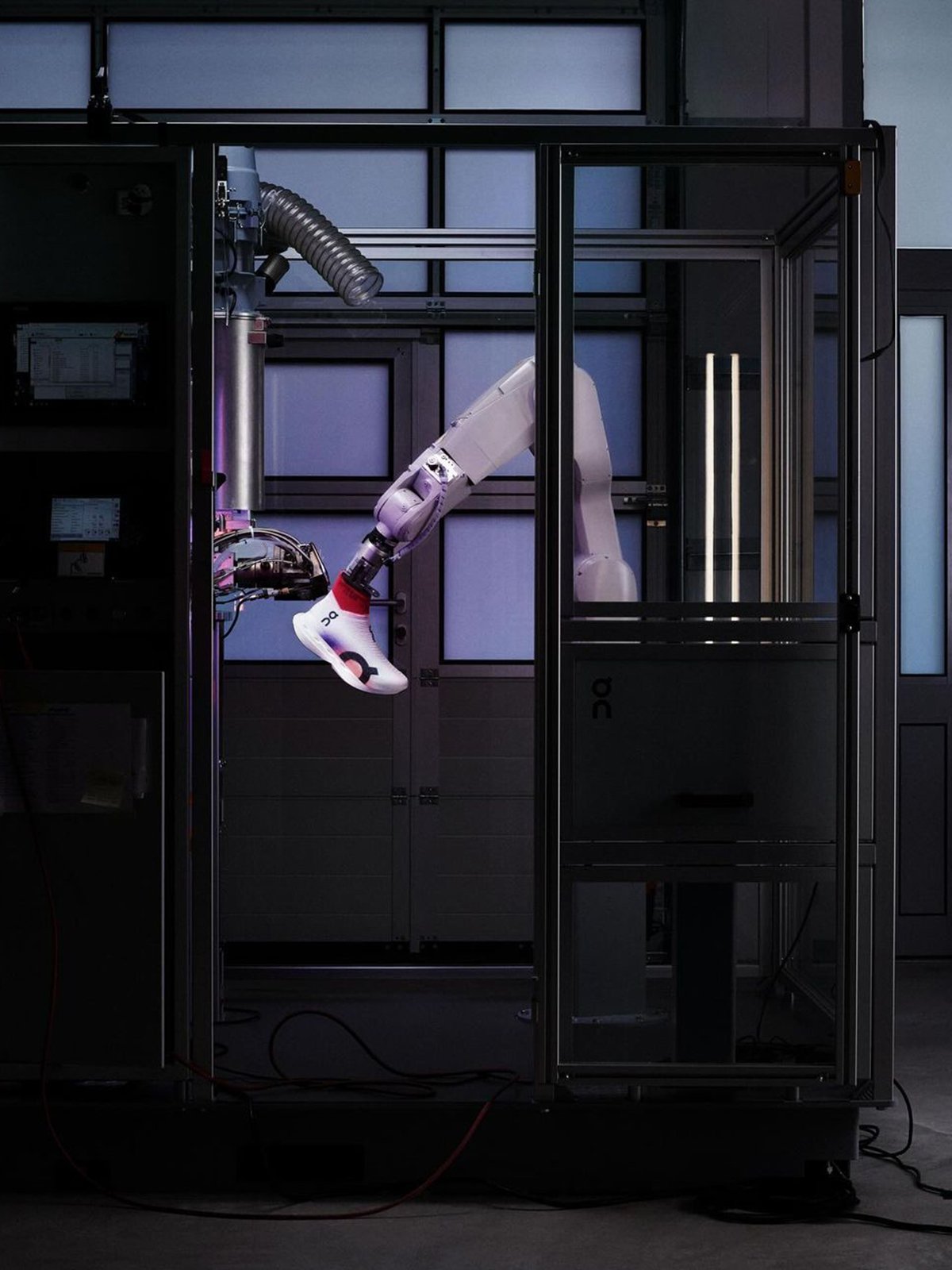

“The main advantage lies in the fact that through a system like this, which works in automation, no mistakes are made. It also allows for greater traceability of the operation, which is also useful for tracing back any problems, and repeatability of the operations performed, which on a practical level is crucial. On the operator's side, it is safer because it allows for no handling of chemicals.”

These are, according to the owners of S.C. Costruzioni Meccaniche, an Empoli-based company specializing in the production of tannery machinery and purification plants, the main strengths of the HotMix systems, which are designed to optimize the mixing and dosing of numerous chemical substances (more or less viscous fluids, powders of various grain sizes to be diluted in liquids, pastes of various consistencies).

While the first reactors existed as early as ten to fifteen years ago, integrated systems such as HotMix have been available for a couple of years and have introduced a number of not inconsiderable improvements. Aimed particularly at companies that make chemicals for tanneries, the machines consist of a tank (sizes range from 500 to 12 thousand liters in volume) inside which the ingredients needed to process the leather are placed: appropriately agitated and heated by the machinery itself, these are homogenized and generate the desired mixture.

The machinery, which can be heated either by electricity or by hot fluids, is offered in numerous configurations, ranging from a simple manually loaded container to a fully automated system. It can be integrated with a batching and weighing system and set up in 4.0 and 5.0 optics, so it can communicate and work with the various companies' management system, returning a constantly updated snapshot of the warehouse situation.

The most advanced configuration with load cells, ingredient adduction through piping, shut-off valves and feed pumps, makes it possible to fully automate the entire process, completely freeing operators from the risks of handling chemicals.