News

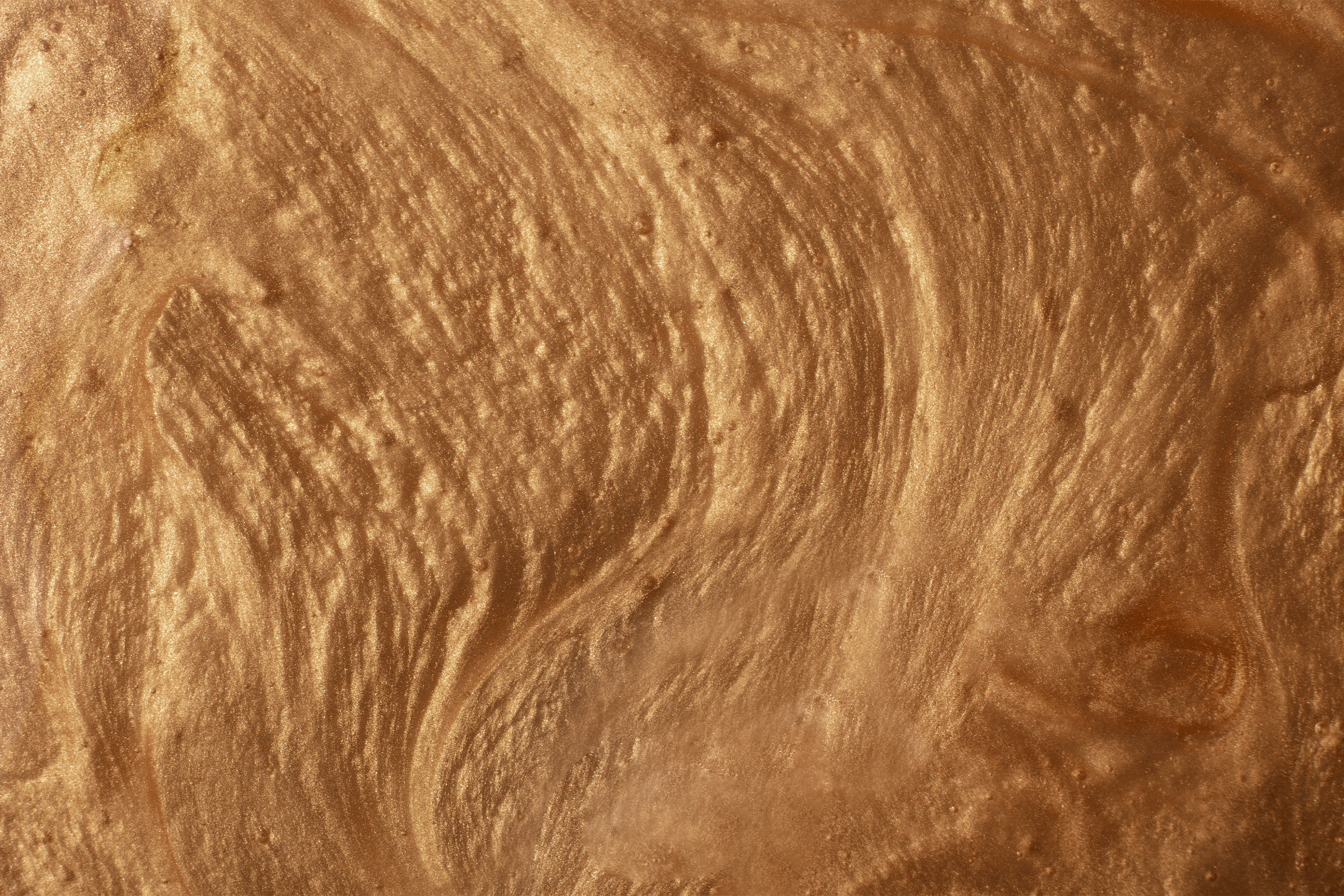

Galvanic industry and metal fashion accessories: here are the news for the A/W 2025 season

The sector of metal accessories for the fashion sector is in full evolution, therefore we interviewed Fulvio Sinisi, R&D and Technical Support Manager – Plating of Legor, a leading company in the galvanic industry, on the latest trends for the F/W 2025 season.

"Some of the trends indicated by industry insiders are already concrete topics and projects for Legor. This is the case of scenarios related to responsible consumption. For years, Legor has been focusing its efforts, for example, on the development of product lines that are totally cyanide-free. Today the company sells cyanide-free gold plating and alkaline copper baths and is in an advanced beta-test phase for silver and bronze plating processes that are always free of cyanides."

Another strand of Legor's research in the choice of sustainable galvanic solutions is the development of completely nickel-free and cobalt-free products with the same performance as the processes containing these metals: «We have recently developed, at the request of a fashion brand, a galvanic process applicable on stainless steel capable of drastically reducing the release values of nickel – explains Sinisi – this in fact disavows the general idea that it is not advisable carry out galvanic applications on this type of substrate".

Another current issue is the simplification of processes with the simultaneous limitation of processing excesses: "With our R&D – says Sinisi – we can have an impact through the development of formulations that allow us to homogenize the metal deposits made as much as possible, reducing waste. As in the case of galvanic baths capable of filing the differences in thickness between the different areas of the frame, thus ensuring deposit thicknesses that are as homogeneous as possible.

Less waste, however, also means something else at Legor: "Our galvanic cycles," concludes Fulvio Sinisi, "are able to reduce processing waste due to quality problems such as adhesion between the different galvanic layers. We have developed products capable of eliminating this problem that have passed the cross-hatching tests in production and have highlighted the performance in the climatic tests of the finished accessories".