News

How is a raffia bag made?

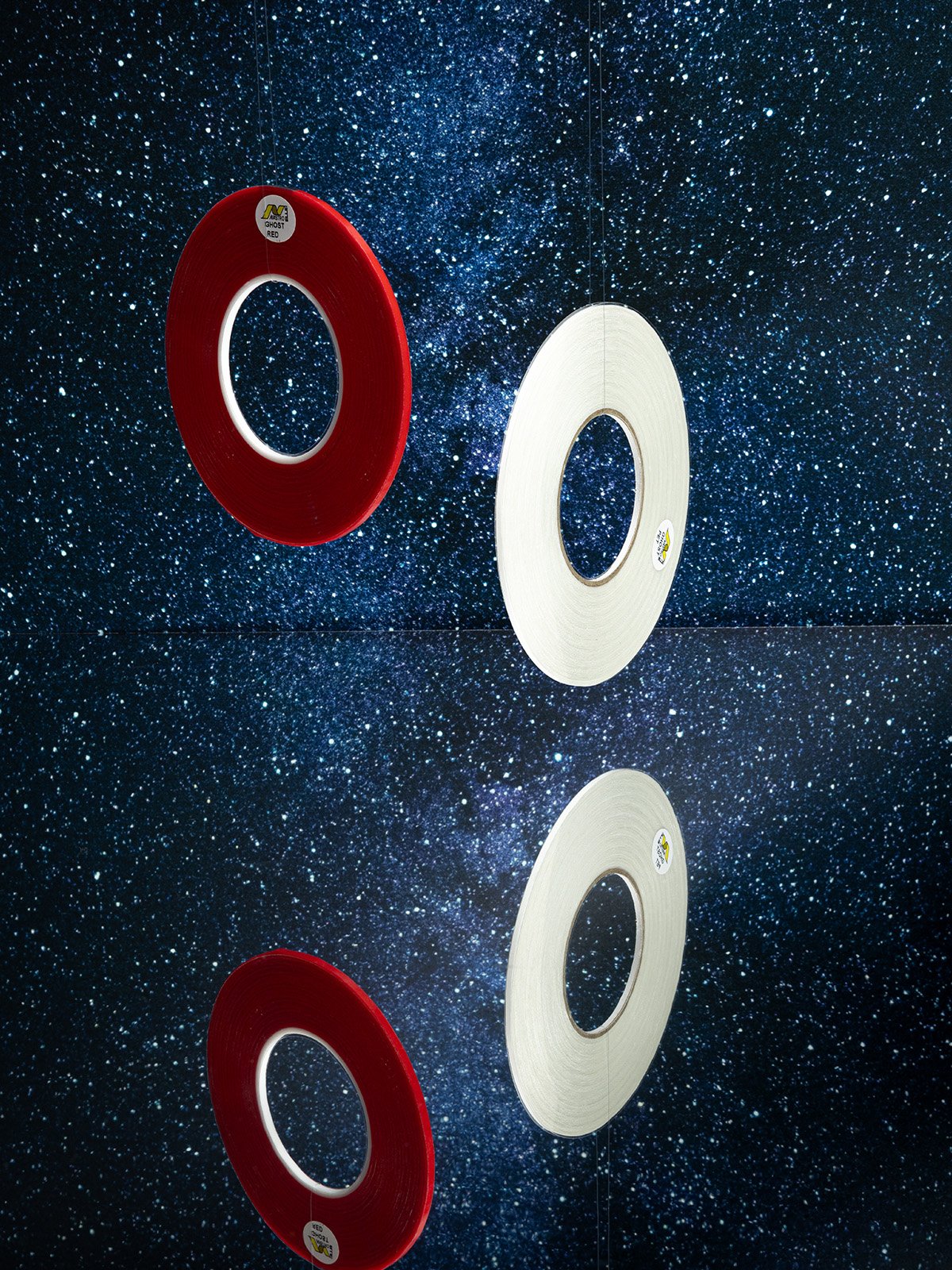

Credit: Saint Laurent

Never a real trend and yet ubiquitous in summer collections, bags made of raffia (or synthetic materials that mimic its effect and processing possibilities) are an evergreen that have had a revamp in recent years thanks to Prada's woven tote bags and that also this season count on it bags that are blowing up on social media, such as Saint Laurent's Icare bag, which is banking on its maxibag launched last spring for a raffia version that is already one of the most desired bags and shown on Instagram and Tik Tok.

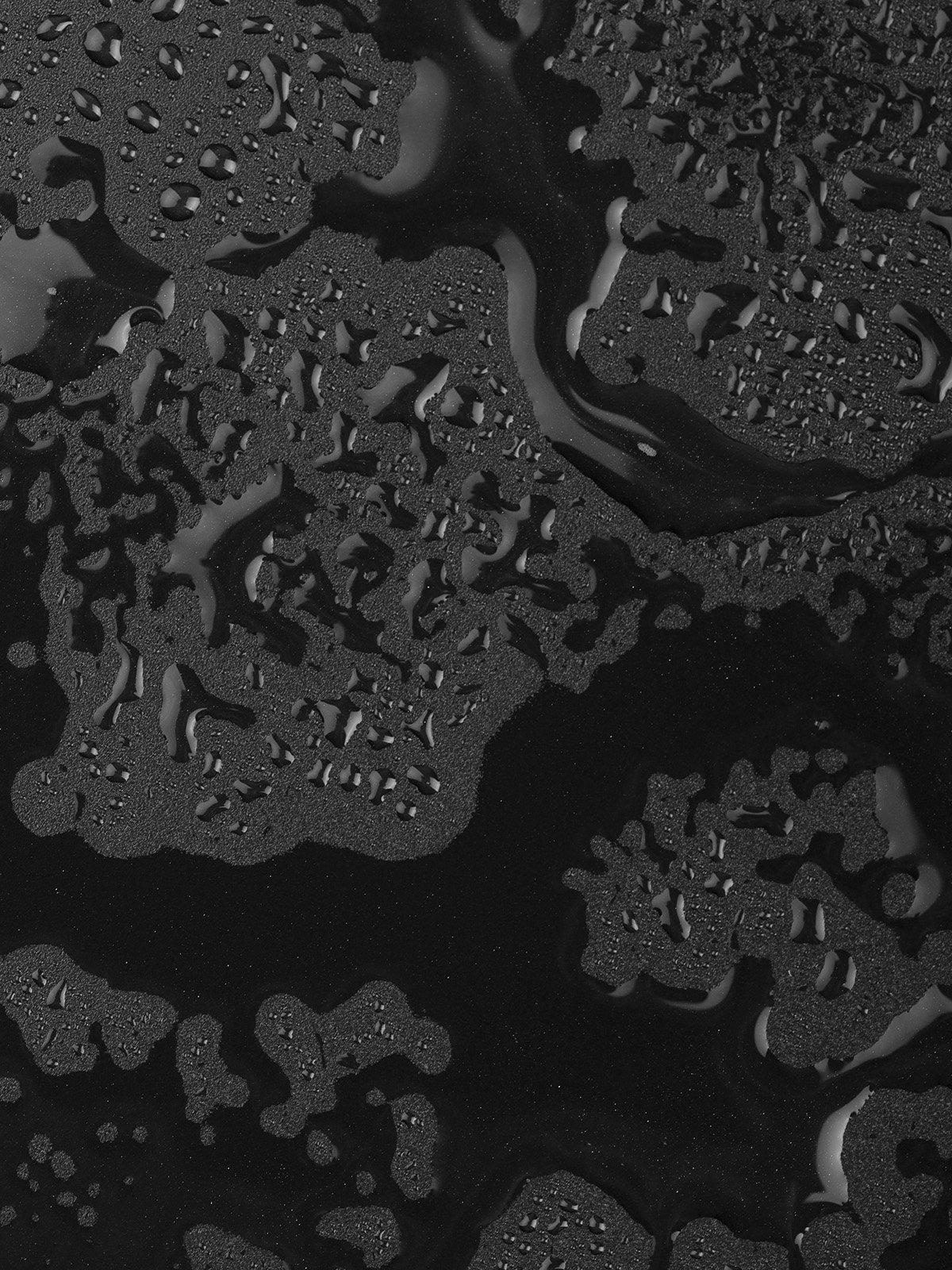

But how do you make a raffia or raffia-like bag? A model like Saint Laurent's requires up to 40 hours of manual weaving, and in the vast majority of cases, when it comes to real raffia or other natural materials such as even straw, it is processed directly in the countries where the material is produced, partly as a matter of environmental and economic sustainability.

“In Italy, finding the workers to produce large quantities is now impossible,” says Leonardo Lami, owner of International Leather Weavings, a company that specializes in weavings and has more than a thousand variations in its catalog. “For luxury products, most of the weaving is done in Albania, but by companies that, like ours, have an office there and can control 100 percent of the production by being able to count on a young workforce eager to learn from the previous generation the secrets of a manual technique that requires patience and dedication, thanks in part to a company that values the craftsmanship that is handed down from mother to daughter.” Thus, the sampler is made in Italy or for those who require a product that is 100 percent made in Italy, and that normally involves leather work.

What about weaving materials that mimic the effect of raffia, such as viscose or cellulose? “They are more expensive but easier to work with, because being synthetic materials they are infinite threads that therefore allow for no imperfections or technical issues. Doing a crochet weave like our grandmothers did with real raffia means dealing with a thread that can easily break or ruin and therefore requires extra attention because the points where the threads join and the flaws have to be hidden,” Lami continues.

How long does it take to process a woven bag? A lot depends precisely on the material, but a lot also depends on its processing and the type of weaving. “It can range from 12 to 40 hours: you have to think that the same weave can totally change depending on the size of the material itself, not only in the degree of difficulty but also in the appearance of the final product.”