News

Vamp Purple, 2024 goal is to certify its green attitude

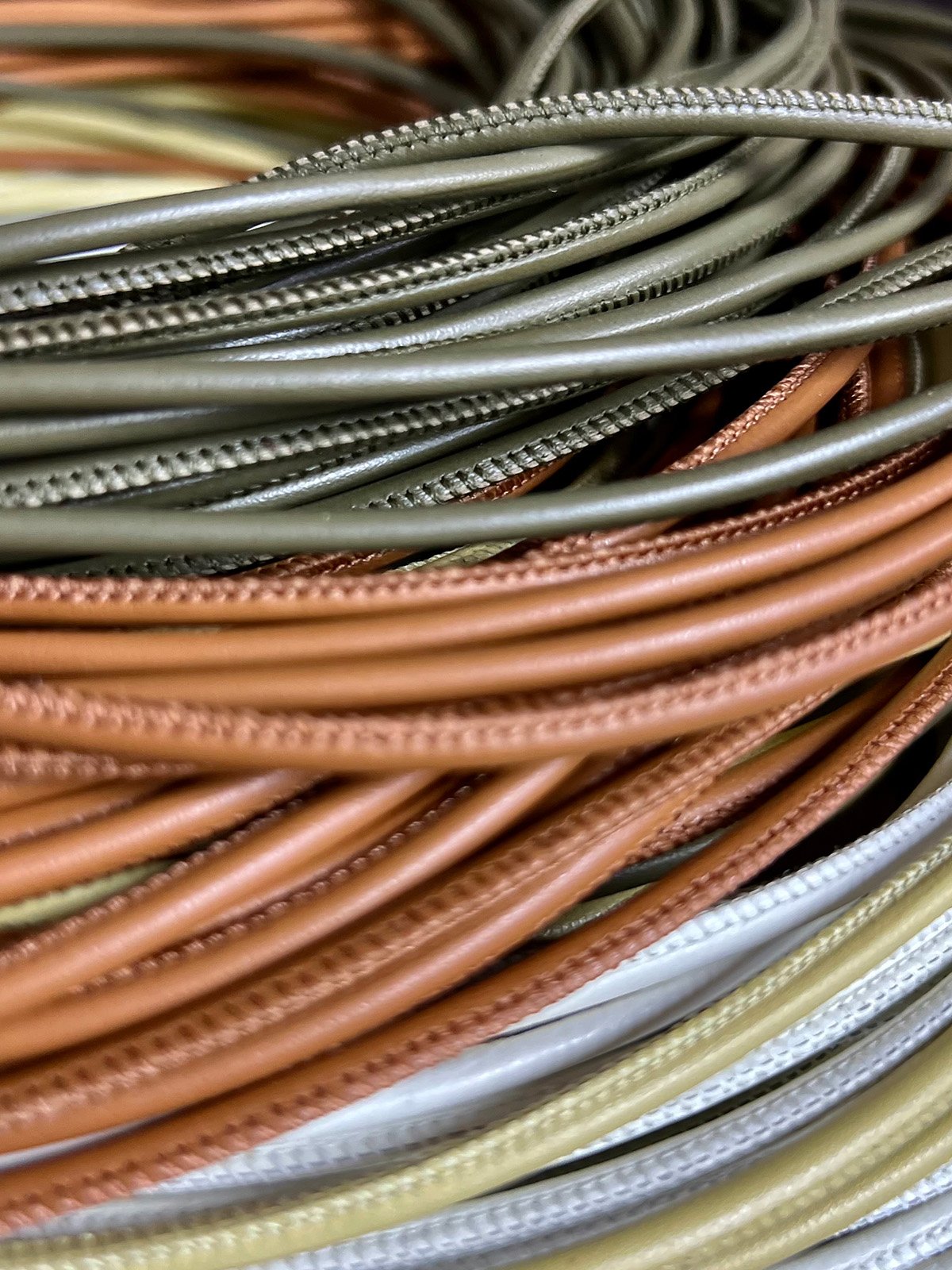

Implementing the Vamp Viola Green Vision. This is the 2024 goal of the Brescia-based company specializing in the production of zamak metal small parts for the fashion industry, which, on the threshold of its 70th anniversary, has decided to give its sustainable approach a further boost. The goal is to obtain environmental certifications by the end of the year-a goal expected to crown a long journey to lessen its impact on the environment.

"Since 2005, Vamp Viola has undertaken a path to reduce its environmental impact that encompasses the entire production cycle," explains Federico Viola, the company's CEO. "This includes constant monitoring to decrease waste in the production processes, the use of renewable energy, thanks to a photovoltaic system that has been active since 2007, and a dry tumbling process with a relevant reduction in water consumption. The use of chemical agents in the entire production chain has also been ruled out, and even on the raw materials front there are strict controls with a green perspective: the zamak used, for example, is of Belgian and Italian origin from highly traced supply chains.

In a market increasingly oriented toward custom products, Vamp Viola is able to manage the complete production cycle to provide exclusive and customized solutions. "Our history is punctuated by generations of collections designed by our style office, which over the years have been adopted by the brands we collaborate with," Viola explains. "The last decade is characterized by an increasingly custom demand, which always starts from one of our sample proposals, then aligned in a sartorial way to the soul of the brand. We also design and produce sample finishes, customized to meet the demands of even the most demanding customers."

The company's strength is precisely the Research and Development Department, thanks to which each project is modulated to achieve maximum customization. "We have brand new software that is constantly being updated and a 3D printer to transform our customers' designs into real objects through the creation of three-dimensional resin prototypes. These processes take place quickly, and we are able to run pre-series if necessary for customer evaluations and modifications before large-scale production."