News

Fratelli Alberti's bet: "centrality of 4.0, but never without an operator"

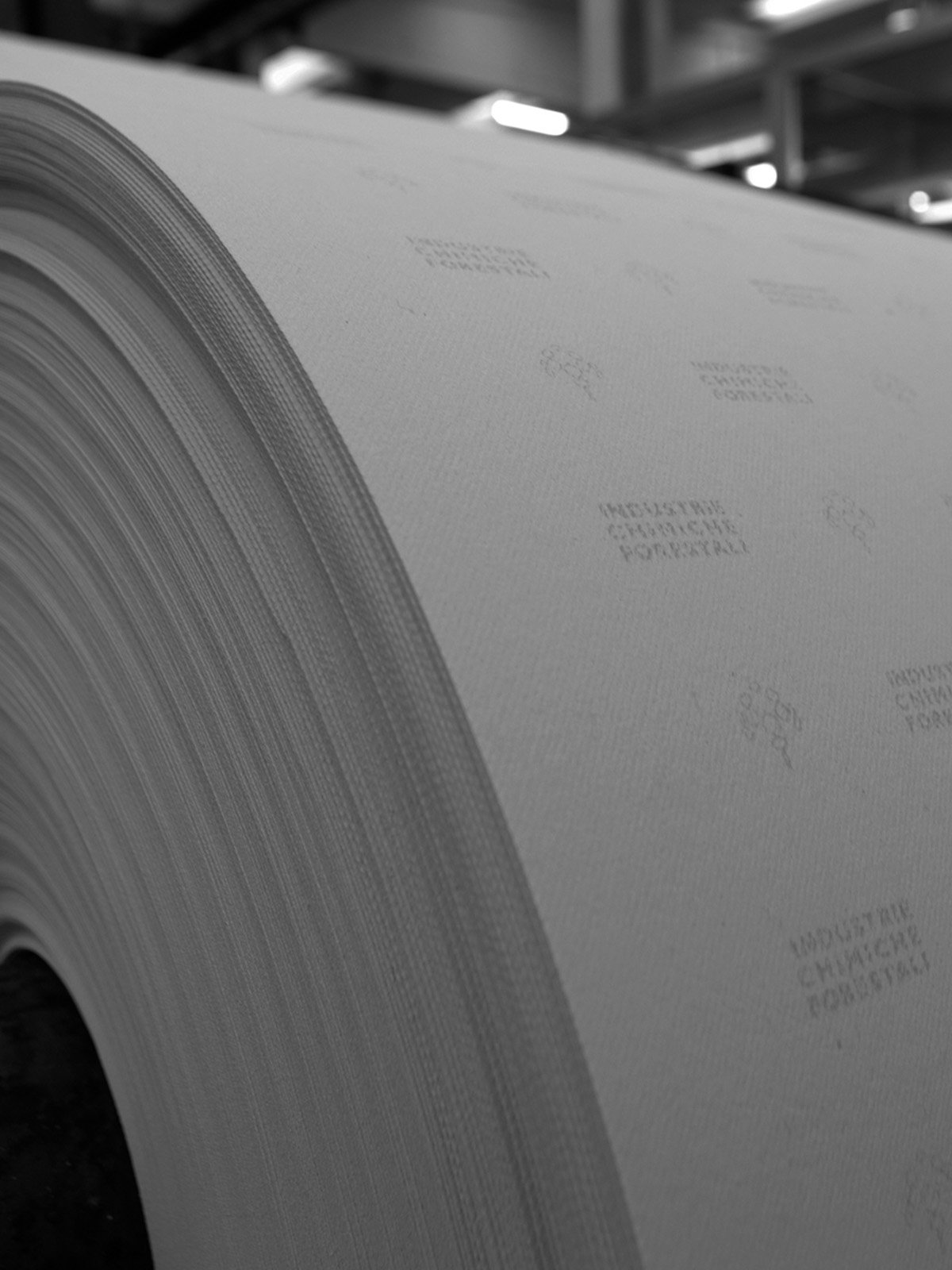

How has the transition to Industry 4.0 changed work in the leather industry? We asked Ilario Monterisi, sales manager of Fratelli Alberti, a Varese-based company that, with its nearly 80 years of history, is now an international benchmark among manufacturers of machines for the leather industry (splitting, fleshing and laminating machines) in all its declinations: leather goods, footwear, automotive, furniture, and nautical.

"It was a transition that marked an improvement in terms of analysis and made production so much easier," Monterisi explains. "I don't think we'll ever get to replace the operator, who continues to represent a great value, but the 4.0 set-up has given so much in terms of programming speed and has made it possible to guarantee constant quality. All of this with reduced waste both in consumption and in material, because more precise machining allows for less waste of the same."

How did you go about adapting the various machines?

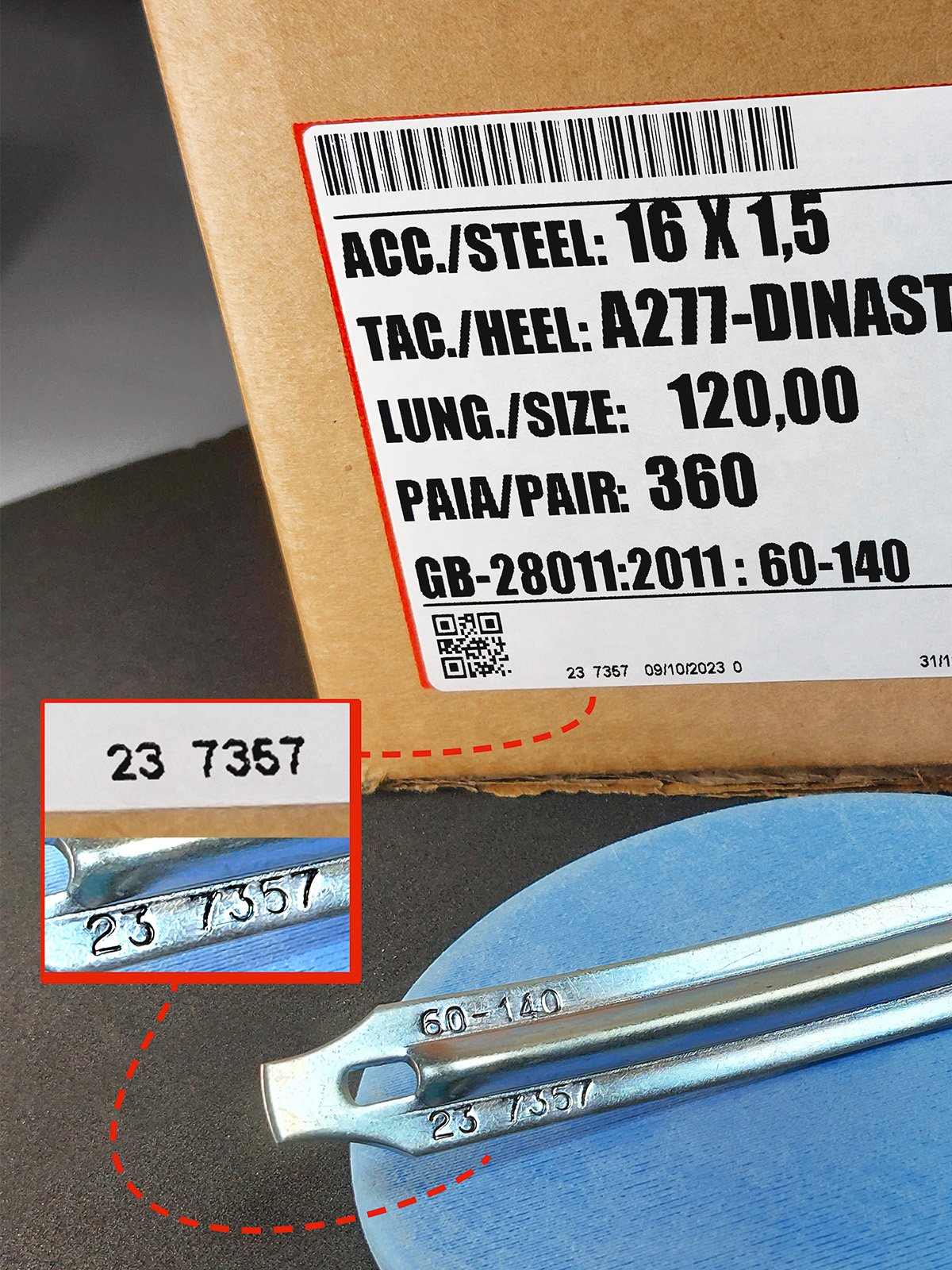

"We started with the AV2 Net fleshing machine, introduced to the market two years ago. A model grafted onto the previous version, which was already computerized, equipped with a more intuitive graphic interface and server connection. We did a lot of work to make the operator's work easier and ensure the highest quality. Another key aspect was safety, with the table presented at Simac 2023, designed for all our fleshing machine models, equipped with a fine dust filter to reduce its dispersion in the working environment and carter guards for moving parts."

And on the splitter and laminator front?

"For splitting machines, a touch screen has been added on the Fav 520 Net and Fav 430 Net models, which allows for the storage of programs and parameters, such as splitting height, transport speed, or engraving time. In the laminating sector we have the AP range, which is having great success because of its ease of use. In addition, with its two alternating carriages it facilitates production, eliminating downtime and is always more precise because the necessary pressure comes from the bottom to the top, stabilizing the position of the material to be processed."

Is all your production now 4.0?

"We have completed the adaptation to 4.0 for all categories of traditional machines, which, although they continue to exist, are obviously less performing in some aspects. However, not all companies have a 4.0-ready set-up, so it is necessary to be alongside them even with traditional products, especially with regard to splitters and fleshing machines."