News

Berti A&P: waterjet technology for extreme precision cutting

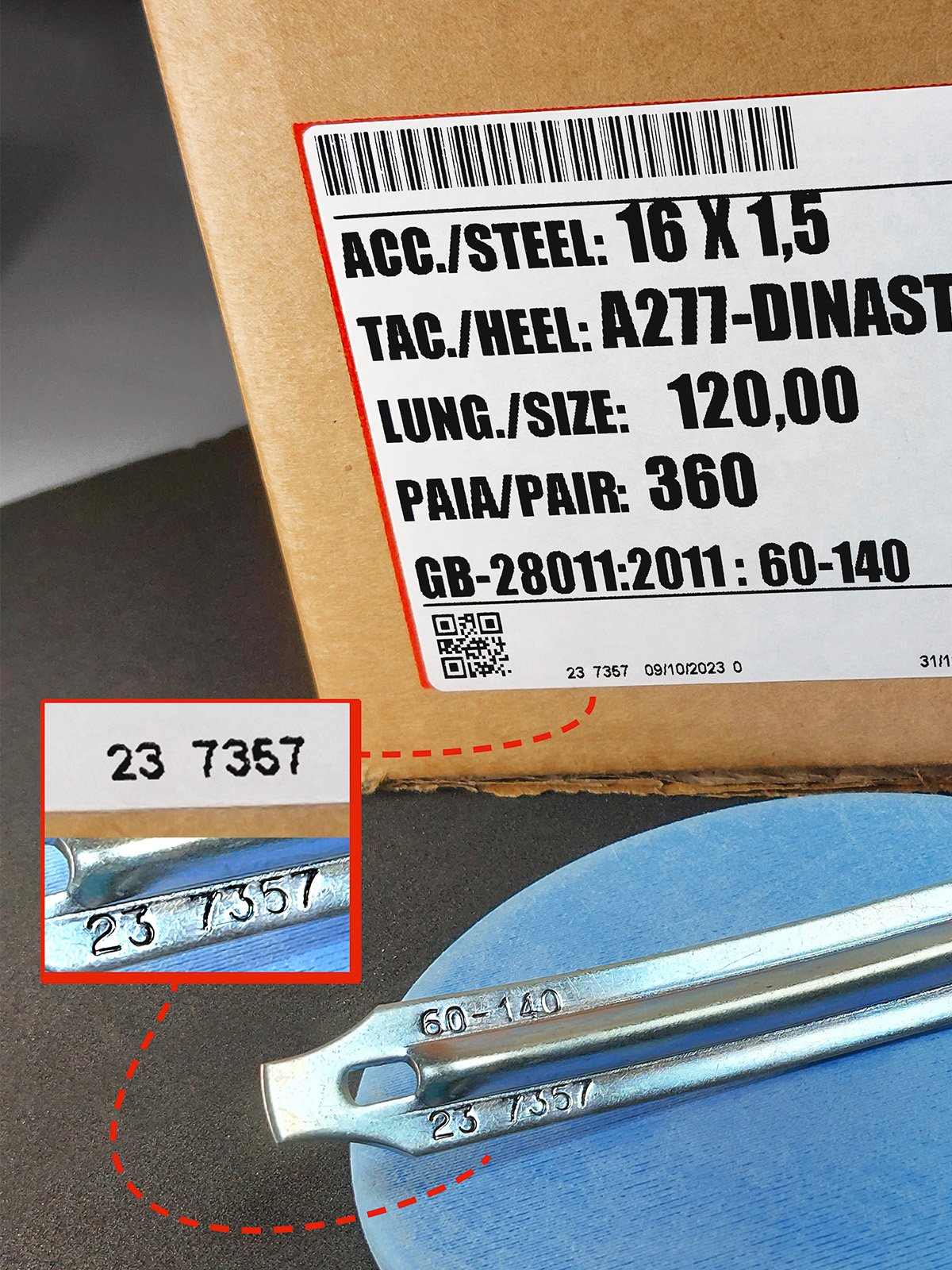

“You insert the piece, program the cut, and the machine adapts to the characteristics of the stone while respecting a basic criterion: not breaking it or stressing it. Plus it does it in a sustainable way.” It is a small revolution that was introduced a few months ago by Berti A&P, an artisanal factory dedicated to the processing of semi-precious stones for the creation of fashion accessories and fine jewelry. It involves a specific machine for cutting stone, which uses a very powerful jet of water that together with a small percentage of abrasive material is able to make cuts of absolute precision.

“We collaborated with a team of U.S. engineers to develop this machinery,” explains Alessio Berti. “It is based on water cutting: a very powerful jet of water that mixed with an abrasive, a very fine crystalline powder from the Australian deserts, manages to perfectly cut the hard stones we work with. And using only the force of the water, the stone is not stressed. We had also done trials with lasers, but the heat goes to affect the molecular composition of the stone, evaporating the water in it and making it brittle. With water, on the other hand, we get very precise cuts without the risk of breakage.”

The small machine is based on Waterjet technology, usually employed on much larger machines used for cutting marble. It also has software capable of recognizing and adapting the cut depending on the hardness of the stone. “It's a fundamental step forward for us who also work for brands, making applications for bags, belts, shoes, jewelry; even very small objects for which extreme precision is needed. It also has virtually zero impact on the environment because we use water and sand, without any chemical agents.”